Novartis Gene Therapies has developed a reproducible manufacturing process. The AAV platform is robust, which allows for flexibility in downstream purification techniques. The optimal AAV serotype can be chosen for different clinical applications in the future.

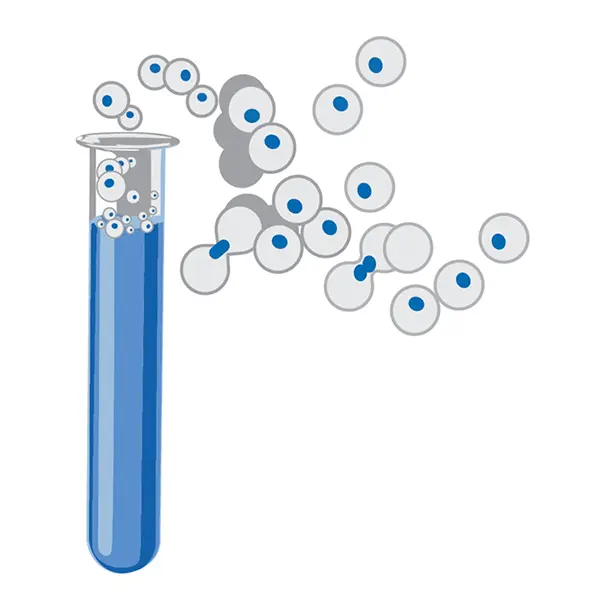

Step 1: Expanding the number of cells

The process starts with one vial containing 10 million cells. For nearly three weeks, they are continuously supplied with fresh nutrients so they can multiply or “expand” in number.

Step 2: Plasmid DNA is added in the bioreactor

Once the cells reach 10 billion in number, they are transferred into a bioreactor where they continue to expand and multiply.

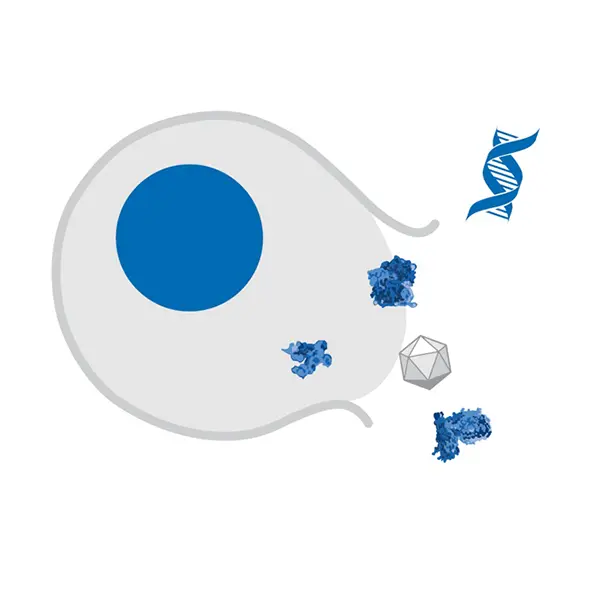

A triple transfection of the cells produces adeno-associated viruses, or AAV vectors, which serve as vehicles to get therapeutic genetic material into a patient’s cells. These are known as transgenes and are specifically designed to replace the function of a gene that patients need.

Step 3: Harvest and filtration

A few days later, the cells are broken open to release the full AAV gene therapy vectors, empty AAV vectors, and other components, like DNA and protein fragments.

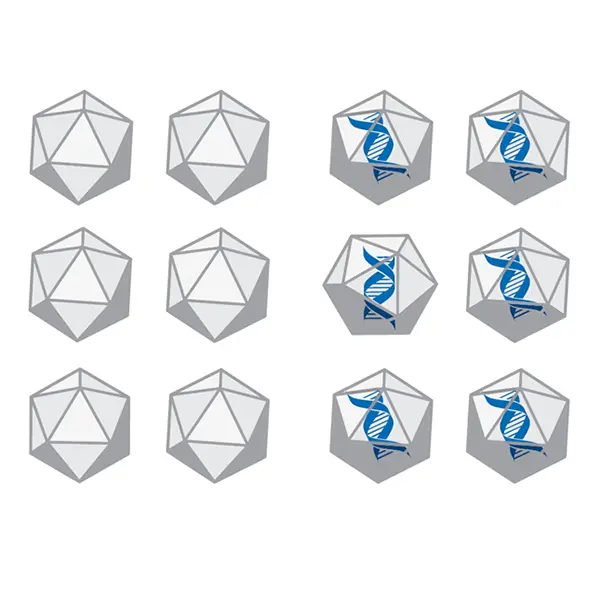

Step 4: Filtration and separation

The product is filtered to remove impurities and meticulously separate the full AAV vectors containing therapeutic genes from the empty ones. The product is then filtered more to ensure the AAV vectors are sterile and ready for use.

Step 5: Fill and finish

The product is loaded into vials and inspected for proper fill and closure. Each time an order comes in, it is custom packed up and shipped out within 24 hours.

The Novartis Gene Therapies Difference

- Novartis Gene Therapies is committed to manufacturing excellence. Gene therapies can be reliably produced and delivered to patients with rare and chronic genetic disorders

- Many safeguards are in place to develop safe and high-quality gene therapies. The active lab facilities have ample storage, backup generators, and real-time alarm systems

- For every person involved in the process, there is a second, real-time verifier as well as a quality reviewer. There is also continuous monitoring of all operations and extensive testing throughout production

- Novartis Gene Therapies efficiently produces a supply of gene therapy. Redundant raw-material suppliers are used, and operations run 24/7 and 365 days a year