Jeff Weers found inspiration for a medical breakthrough in an unlikely place – a baseball field. His passion for the sport led to a big idea: a new way of getting inhaled medicine past the natural obstacle course of the human mouth and throat to reach the lungs and treat respiratory diseases.

VIDEO

VIDEO

“Scientists know that their best ideas do not always present themselves in the lab,” said Weers. “Many of the things you see around you in your daily life can sometimes present solutions to the most intractable problems in science.”

Millions of people around the world use inhalers every day to treat lung disorders. The problem is that some of the medicine they inhale gets stuck on the way and does not reach its target, limiting effectiveness. The story of how Weers devised an innovative solution to this problem and then worked for almost two decades to turn it into reality illustrates the mixture of inspiration and dogged determination often required to advance medical science.

Weers' solution was to develop a new kind of drug particle, one capable of curving past the bend in the throat.

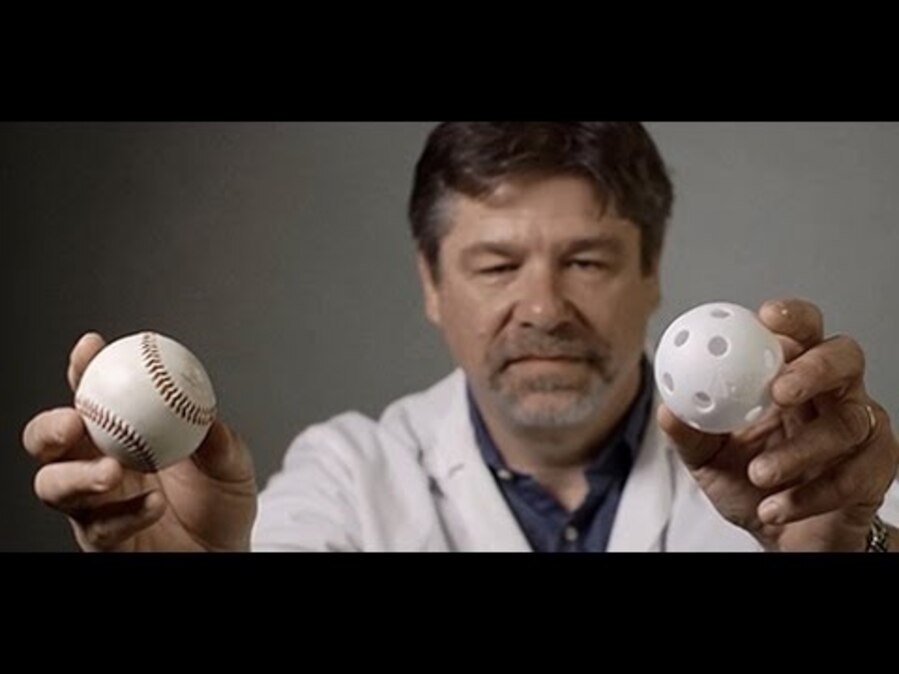

Weers realized he knew an object that would curve in just the right way – the plastic balls he used as a boy in baseball practice. These hollow, perforated balls move much more slowly than solid baseballs and are easier to coax into a curving trajectory. "We could do some wicked things with these plastic children’s balls in terms of spins and curves, and that’s what got me thinking."

Weers believed that reproducing the structure of a perforated ball on a microscopic scale might lead to a new kind of drug particle that could curve in the right way after being inhaled. He committed himself to converting his innovative idea into reality, little realizing how long his quest would take.

Weers had to confront a key challenge in bringing his theory to life: how to make these microscopic particles to a precise and consistent size.

Achieving an exact size and structure of particle would be essential. Any inconsistencies or irregularities might cause particles to behave differently, such as adhering to each other and forming lumps that would not travel in the desired direction.

Traditionally, powders are made by milling the drug into small particles. These particles have flat surface areas that form strong joins and makes them more likely to adhere to each other. To get around this problem, large particles of inactive substances like lactose are added to prevent the powder from clumping together. However, this has the effect of limiting the quantity of active ingredient that can be packed into each dose. The spherical shape of Weers’ engineered particles reduced the risk of them sticking.

Many of the things you see around you in your daily life can sometimes present solutions to the most intractable problems in science.

Jeff Weers, Particle Engineer, Novartis

Over the course of almost two decades, Weers experimented in the laboratory with ways to produce particles barely a micron across – less than the width of a human hair.

Weers studied particles in numerous consumer goods to try to find ways of making them in a more consistently round, perforated shape. Spray drying of emulsions is a major area of research in food science, particularly with dairy products. Powdered milk particles, while far too big for Weers’ purposes, are produced through a commercial drying process. Developing some sort of emulsion appeared to be a possible answer, Weers thought.

By using different techniques and trialing different materials, Weers believed he was finally nearing a possible answer in the shape of a new type of solution called a homodispersion, a mix of tiny droplets of medication in an oil-based emulsion.

Weers' patented process involved first atomizing the liquid to form droplets and then spray drying them in a hot gas. As the oil in the emulsion evaporated, it left behind a residue of tiny dried drug particles of a consistent shape and size. These tiny particles were collected via a cyclone separator, a device that works on the same principle as some modern vacuum cleaners – using an internal vortex to remove particulates from an air stream without the use of filters.

The active drug ingredient was introduced into the particles and then produced as a dry powder, ready for inhalation.

The next task was to make these patented drug particles in the industrial quantities required. Weers needed to scale up experiments conducted in closely-controlled lab conditions into a large-scale manufacturing process.

Weers also worked to develop a manufacturing process capable of making particles for a wide range of drugs. Drugs produced with these engineered particles come in solutions, suspensions – where the particles aren’t fully dissolved – or dry powder. The complexities involved in scaling up the manufacturing process mean that the Novartis facility in San Carlos, California, is the only one in the world where the commercial spray drying process is used and the particles are made.

By 2010, the first medications for lung disorders using the engineered particles reached patients as part of clinical trials, and they became commercially available in 2013. Novartis is now trialing the particle engineering technology with other inhaled pharmaceuticals developed by three of the world’s top ten drug companies.

Weers, meanwhile, retains his enthusiasm for baseball. Although he doesn’t pitch quite as fast as he did when he was an 18-year-old college freshman, he’s always pleased when friends ask him to play.

“I love baseball. I know my professors at university felt I played too much. But had they realized it would spark the idea for a major medical innovation, perhaps they’d have encouraged my classmates to join me as well.”